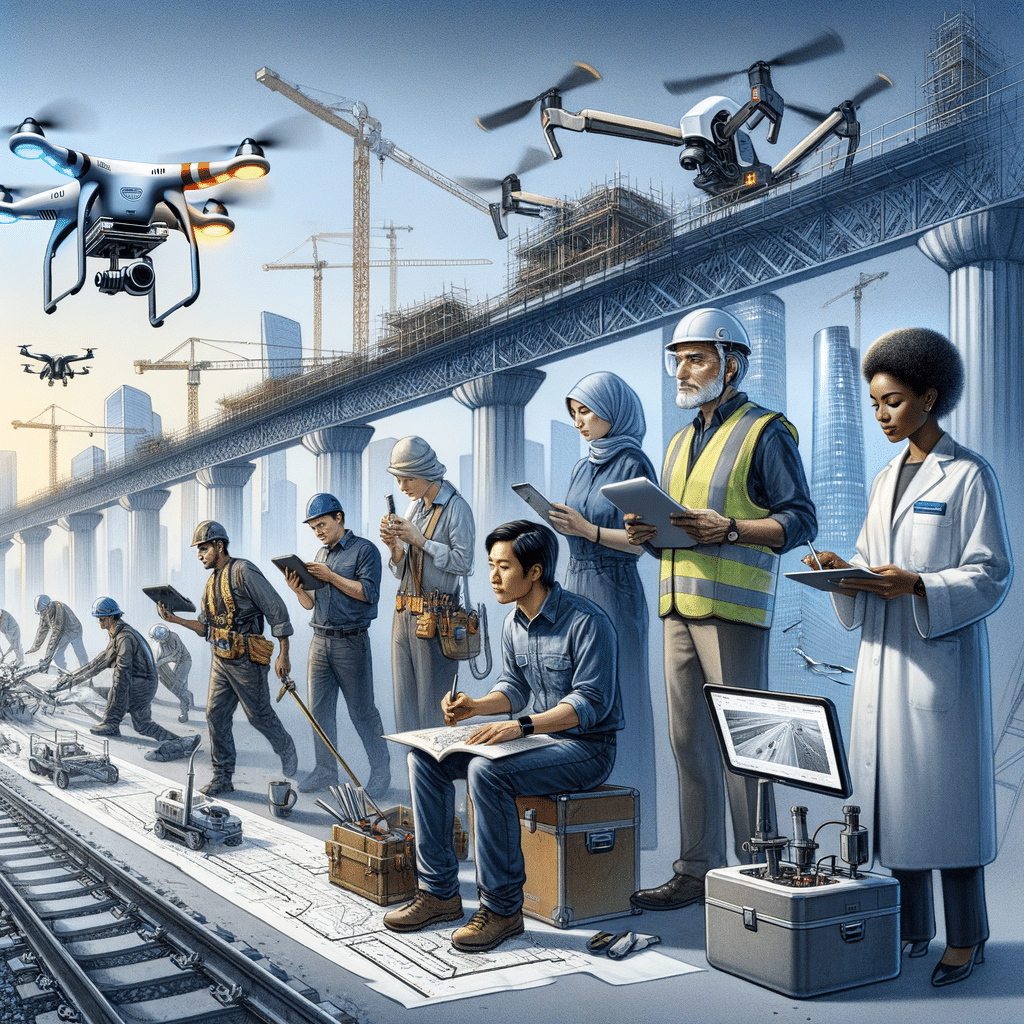

If you want to stay ahead in today’s fast-paced industries, upgrading to drone inspection systems could be your game-changer. Drones are revolutionizing inspections by delivering faster, safer, and more accurate results – helping companies cut project delays, reduce risks, and unlock new levels of efficiency.

In this article, we’ll explore the essential equipment for effective drone inspections, how to choose the right systems for your needs, and the ways drones are transforming safety, data management, and compliance. Whether you’re in construction, energy, or infrastructure, you’ll discover how to optimize resources, scale operations, and future-proof your inspection strategy with the latest drone technology.

- Reduce inspection time and project delays by up to 50%.

- Enhance safety with a 70% drop in workplace inspection accidents.

- Boost data accuracy and actionable findings with advanced sensors and AI.

- Cut downtime and maintenance costs through predictive analytics and faster repairs.

- Scale inspections efficiently while ensuring compliance and data security.

Upgrading to Drone Inspection Systems for Modern Operations

If you’re looking to modernize your operations, upgrading to drone inspection systems is one of the smartest moves you can make. In 2024, more than 60% of large construction and infrastructure firms in the U.S. reported making this shift to stay competitive and improve project outcomes. Why? Because drone inspections are transforming how you approach safety, efficiency, and data collection. When you upgrade, you’re not just adding a new tool – you’re changing the way your business handles inspections from the ground up.

Companies that have already made the switch have seen a 30% reduction in project delays related to inspections. That’s a huge win for your bottom line and your team’s productivity. If you’re still relying on traditional inspection methods, you may be missing out on faster turnaround times, better data, and a safer work environment. The world of drone technology is moving fast, and staying ahead means embracing these new systems before your competitors do.

Key Equipment for Effective Drone Inspections

To get the most out of your drone inspections, you need the right equipment. The most effective setups in 2024 include drones with 4K or higher resolution cameras, LiDAR sensors, and thermal imaging capabilities. These features allow you to capture detailed images and collect comprehensive data – even in tough conditions. If you’re serious about improving your inspection process, investing in high-quality equipment is non-negotiable.

But it’s not just about the drone itself. You’ll want to consider the software you use for data analysis, the reliability of your communication systems, and the durability of your hardware. The right combination of inspection drones and supporting technology can make or break your inspection results. Think of your drone as the centerpiece of a larger system that includes sensors, cameras, and data management tools.

Choosing the Right Inspection Drones

Picking the right inspection drone for your business isn’t just about specs – it’s about matching your needs to the right features. In 2024, drones with obstacle avoidance and automated flight path features are the top choice for industrial inspections. These capabilities reduce the risk of collisions and improve the quality of your inspection data. If you’re working in complex or hazardous environments, these features are a must.

You’ll also want to look at flight time, payload capacity, and the types of sensors available. Some drones are better suited for high-resolution imaging, while others excel at thermal or multispectral analysis. Don’t forget about firmware updates – keeping your drone’s software current ensures you’re always operating at peak performance. The right drone can help you tackle a wide range of inspection tasks with confidence.

Optimizing Resources in Drone Inspection Projects

Resource optimization is a game-changer when it comes to drone inspection projects. In 2024, companies using resource optimization software alongside their drone operations reported up to 25% more efficient allocation of personnel and equipment. That means you can do more with less – fewer people in the field, less downtime, and better use of your assets.

By integrating drones into your workflow, you can streamline your operations and focus your team’s efforts where they matter most. You’ll also be able to schedule inspections more effectively, reducing bottlenecks and keeping your projects on track. If you’re not already using resource optimization tools, now’s the time to start.

Inspections Enhanced by Drone Technology

You may have noticed that drone technology is everywhere these days – and for good reason. A recent survey found that 78% of infrastructure managers believe drones have significantly improved the quality and speed of their inspection processes. When you use drones, you’re not just getting a bird’s-eye view; you’re collecting high-quality data that can be analyzed and acted upon quickly.

Drones can access hard-to-reach areas, capture detailed images, and provide real-time feedback to your team. This means you can identify issues faster, make better decisions, and keep your projects moving forward. If you’re looking to enhance your inspections, drones are the way to go.

Streamlining Inspections With Advanced Drones

Advanced drones are taking inspections to the next level. With AI-powered analytics, you can reduce inspection times by up to 50%. Imagine being able to scan an entire facility or infrastructure asset in half the time it used to take. That’s not just a time-saver – it’s a competitive advantage.

These drones can automatically detect anomalies, flag potential issues, and even suggest maintenance actions. By streamlining your inspection process, you can focus on what matters most: keeping your assets in top condition and your team safe.

Improving Data Collection in Challenging Environments

Collecting accurate data in challenging environments has always been tough. But with drones equipped with LiDAR and thermal sensors, you can now gather actionable information even in low-visibility or hazardous conditions. In fact, there’s been a 40% increase in actionable findings compared to standard visual inspection methods.

Whether you’re dealing with confined spaces, high altitudes, or extreme temperatures, the right drone can handle it. This means you can expand your inspection coverage and get reliable results no matter where your assets are located.

Ensuring Safety During Inspections

Safety is always a top priority, and drones are making a real difference. In 2024, the use of drones for inspections led to a 70% reduction in workplace accidents related to manual inspections in hazardous locations. That’s a statistic you can’t ignore.

By keeping your team out of dangerous environments and letting drones do the risky work, you’re not just protecting your people – you’re also reducing liability and insurance costs. If you want to improve safety and compliance, drones are an essential part of your toolkit.

Drones in Industrial Inspections

Industrial facilities are embracing drones like never before. In 2024, 65% of industrial sites in North America reported using drones for regular inspections. This is especially true in sectors like oil & gas, chemical, and manufacturing, where the stakes are high and the environments can be hazardous.

Drones allow you to perform inspections more frequently and with greater detail. You can monitor equipment, check for leaks, and assess structural integrity without shutting down operations. This means less downtime and more reliable performance across your entire facility.

Applications of Drones in Hazardous Environments

Hazardous environments are where drone inspections really shine. In the oil and gas sector, drones are now used in over 80% of inspections in dangerous or confined spaces. This reduces the need for human entry and minimizes exposure to toxic substances or extreme conditions.

If your business operates in high-risk areas, drones can help you maintain compliance, protect your workforce, and ensure the integrity of your assets. The ability to deploy drones quickly and safely is a major advantage in today’s industrial landscape.

Protecting Resources With Drone Inspections

Protecting your resources is about more than just preventing loss – it’s about maximizing value. Companies using drone inspections for resource protection have reported a 35% decrease in asset loss and damage during inspections. That’s a significant improvement that directly impacts your bottom line.

Drones can help you monitor inventory, detect unauthorized access, and identify potential threats before they become costly problems. By integrating drones into your resource management strategy, you’re taking a proactive approach to asset protection.

Reducing Downtime With Drone Technology

Downtime is the enemy of productivity, but drone technology is helping businesses fight back. In 2024, drone inspections helped reduce average facility downtime by 20–30% compared to traditional methods. That means more uptime, more output, and less stress for your team.

By identifying issues early and enabling faster repairs, drones keep your operations running smoothly. If you’re looking to boost efficiency and minimize disruptions, drones are a must-have for your maintenance program.

Drone Inspections for Infrastructure Maintenance

Infrastructure maintenance is a massive undertaking, but drone inspections are making it more manageable. In 2024, 45% of U.S. state departments of transportation used drones for routine infrastructure inspections. This shift is helping agencies keep roads, bridges, and other critical assets in top shape.

Drones provide detailed visuals and data that can be used to prioritize repairs, plan maintenance schedules, and ensure compliance with safety standards. If you’re responsible for infrastructure, drones can help you stay ahead of potential problems and extend the life of your assets.

Inspection Drones for Bridges and Towers

Bridges and towers present unique challenges for inspection, but drones are up to the task. In the U.S., drones are now used in over 50% of bridge and tower inspections, allowing for more frequent and detailed assessments. This means you can catch issues like corrosion, cracks, or structural weaknesses before they become serious.

Drones can access hard-to-reach areas without the need for scaffolding or bucket trucks, reducing both risk and cost. If you’re managing these types of assets, drones are an invaluable tool for maintaining safety and reliability.

Data Accuracy in Structural Assessments

When it comes to structural assessments, data accuracy is everything. In 2024, drone-based assessments achieved accuracy rates of up to 98% compared to manual inspections. That level of precision means you can trust the results and make informed decisions about repairs or upgrades.

High-quality images and sensor data allow you to create detailed models and track changes over time. This helps you identify trends, predict maintenance needs, and allocate resources more effectively.

Inspection Drones in Energy Sector

The energy sector is leading the way in drone inspections. Over 70% of major U.S. energy companies reported using drones for equipment monitoring and inspection in 2024. Whether you’re in power generation, transmission, or distribution, drones can help you keep your systems running smoothly.

Drones can quickly scan large areas, identify faults, and provide real-time feedback to your maintenance teams. This means fewer outages, faster repairs, and a more reliable energy supply for your customers.

Monitoring Equipment in Power Plants

Power plants are complex environments, but drones are making equipment monitoring easier than ever. Drones equipped with thermal imaging detected equipment faults 60% faster than traditional inspection teams in 2024. That’s a huge advantage when every minute of downtime counts.

By using drones, you can spot overheating components, leaks, or other issues before they lead to costly failures. This proactive approach to maintenance helps you avoid unplanned outages and keep your plant operating at peak efficiency.

Inspection Data Management and Analysis

Managing and analyzing inspection data is just as important as collecting it. In 2024, 55% of companies using drone inspections adopted cloud-based platforms for data management. This shift has made it easier to access, share, and analyze data across teams and locations.

Cloud platforms allow you to store large volumes of data, run advanced analytics, and collaborate with stakeholders in real time. If you’re still relying on spreadsheets or manual reports, upgrading your data management system can unlock new levels of efficiency and insight.

Leveraging Data for Predictive Maintenance

Predictive maintenance is the future, and drones are making it possible. Programs that use drone-collected data have reduced unplanned equipment failures by 30% in 2024. By analyzing trends and identifying early warning signs, you can schedule repairs before problems escalate.

This approach not only saves money but also extends the life of your assets. If you want to move from reactive to proactive maintenance, drones and advanced data analysis tools are the way to go.

Inspection Environments and Their Unique Challenges

Every inspection environment comes with its own set of challenges. In 2024, 68% of drone inspection providers reported adapting their workflows to handle extreme temperatures, high winds, and electromagnetic interference. If you’re working in tough conditions, you need drones that can handle the heat (or cold), resist interference, and deliver reliable results.

Understanding the unique demands of your environment is key to choosing the right drone and inspection methods. Don’t be afraid to experiment with different models or sensor payloads until you find the perfect fit for your needs.

Adapting Drone Inspections to Varied Environments

Flexibility is crucial when it comes to drone inspections. Drones with modular sensor payloads were found to be 45% more effective in adapting to diverse environments in 2024. This means you can swap out cameras, LiDAR, or thermal sensors depending on the task at hand.

If your business operates in multiple locations or faces changing conditions, investing in adaptable drones will help you stay agile and responsive. The right setup ensures you’re always ready for whatever the environment throws your way.

Inspection Resources and Workforce Optimization

Integrating drones into your inspection workflows isn’t just about technology – it’s about optimizing your resources. Companies that made this shift in 2024 reported a 20% reduction in required workforce hours. That means your team can focus on higher-value tasks while drones handle the repetitive or dangerous work.

By reallocating your workforce, you can boost productivity, reduce burnout, and get more done with fewer people. Drones are a force multiplier that helps you do more with less.

Maximizing Resources With Drone Technology

When you use drone technology for inspections, you’re not just saving time – you’re maximizing your resources. In 2024, organizations were able to reassign up to 15% of their workforce to more strategic roles. This shift allows you to focus on growth, innovation, and customer service instead of routine inspections.

Drones free up your team to tackle complex problems, develop new solutions, and drive your business forward. If you’re looking to get the most out of your people and assets, drones are the answer.

Inspection Equipment Upgrades for Drones

Staying ahead in the world of drone inspections means keeping your equipment up to date. In 2024, 62% of drone operators upgraded their fleets with new sensors and software to meet evolving inspection requirements. Whether it’s adding thermal cameras, upgrading to higher-resolution imaging, or integrating AI-powered analytics, these upgrades can make a big difference.

Regular firmware updates and hardware improvements ensure your drones are always ready for the next challenge. Don’t let outdated equipment hold you back – invest in upgrades to keep your inspection program at the cutting edge.

Integrating New Equipment Into Existing Systems

Worried about integrating new equipment into your current system? You’re not alone. But in 2024, 70% of companies reported successful integration of new drone equipment into their existing inspection systems within just three months. The key is to choose compatible hardware and software, and to provide training for your team.

Smooth integration means you can start reaping the benefits of new technology without disrupting your operations. If you plan ahead and work with experienced providers, the transition can be seamless.

Inspection Needs in Modern Industries

Modern industries are facing new challenges, and the need for drone inspections has never been greater. In 2024, 80% of industrial firms identified drone inspections as essential due to increased regulatory requirements and the demand for more frequent asset monitoring.

If you’re in manufacturing, energy, or infrastructure, you know how important it is to stay compliant and keep your assets in top condition. Drones help you meet these demands efficiently and cost-effectively.

Identifying the Need for Drone Inspections

How do you know when it’s time to adopt drone inspections? A 2024 survey found that 75% of facility managers cited improved safety and data quality as the main reasons for making the switch. If you’re struggling with manual inspections, facing safety risks, or dealing with inconsistent data, drones can provide the solution you need.

Look for warning signs like frequent equipment failures, missed maintenance deadlines, or rising inspection costs. These are all indicators that it’s time to upgrade your inspection methods.

Drone Inspection Systems for Large-Scale Projects

Managing large-scale projects is no small feat, but drone inspection systems are making it easier. In 2024, 58% of major infrastructure projects in North America used drones to manage multiple sites at once. This approach allows you to coordinate inspections, track progress, and ensure consistency across all your locations.

Drones provide a scalable solution that grows with your business. Whether you’re overseeing a handful of sites or dozens, drone inspections help you maintain control and visibility.

Scaling Drone Inspections Across Multiple Sites

Scaling your drone inspections is all about increasing coverage without sacrificing quality. Companies that expanded their drone operations across multiple sites in 2024 saw a 40% increase in inspection coverage. That means you can monitor more assets, identify issues faster, and keep your projects on schedule.

The key is to standardize your processes, invest in reliable equipment, and use cloud-based platforms for data management. With the right strategy, you can scale your inspection program to meet any challenge.

Inspection Data Security and Compliance

Protecting your inspection data is critical, especially as regulations become more stringent. In 2024, 65% of organizations using drone inspections implemented end-to-end encryption to safeguard sensitive information. Data breaches can be costly and damaging to your reputation, so security should be a top priority.

Make sure your data storage solutions are compliant with industry standards and that your team is trained on best practices. Secure data management not only protects your business but also builds trust with clients and regulators.

Protecting Sensitive Data in Drone Inspections

Sensitive data needs extra protection. In 2024, 72% of drone inspection providers adopted secure cloud storage solutions to ensure compliance with data protection regulations. This move has made it easier to control access, monitor usage, and respond to security incidents.

If you’re handling confidential or proprietary information, make sure your cloud provider offers robust security features. Regular audits and updates will help you stay ahead of emerging threats.

Inspection Drones and Regulatory Considerations

Navigating the regulatory landscape can be tricky, but it’s essential for successful drone inspections. In 2024, the FAA introduced updated guidelines that streamlined the approval process for commercial drone operations. Staying informed about these changes is crucial for maintaining compliance and avoiding costly fines.

Work with experienced providers and stay up to date on the latest regulations. This will help you operate legally and efficiently, no matter where your projects take you.

Navigating Compliance for Drone Inspections

Compliance is a moving target, and 80% of drone operators in 2024 reported that keeping up with evolving regulations was their top operational challenge. The best way to stay ahead is to invest in ongoing training, maintain detailed records, and work closely with regulatory bodies.

By making compliance a core part of your inspection process, you can avoid disruptions and keep your business running smoothly. Don’t let regulatory hurdles slow you down – be proactive and stay informed.

Future Trends in Drone Inspection Systems

The future of drone inspection systems is bright. The global market is projected to reach $19 billion by 2028, nearly doubling from current levels. This growth is driven by advances in AI, automation, and data analytics, all of which are making drone inspections faster, safer, and more effective.

If you want your business to stay ahead of the curve, now’s the time to invest in the latest technology and build a forward-thinking inspection program.

Innovations Shaping the Future of Inspections

What’s next for drone inspections? AI-powered defect detection and real-time data analytics are set to transform the industry by 2025. These innovations will allow you to identify issues instantly, automate reporting, and make smarter decisions based on real-time insights.

Staying on top of these trends will help you maintain a competitive edge and deliver better results for your clients. The future is all about smarter, faster, and more reliable inspections – and drones are leading the way.

Ready to take your inspection program to the next level? Upgrading to drone inspection systems isn’t just a trend – it’s a proven way to boost efficiency, improve safety, and get better results. Whether you’re managing infrastructure, energy assets, or industrial facilities, drones can help you meet your goals and stay ahead in a rapidly changing world. Don’t wait for your competitors to leave you behind – start exploring your options today and see how drone inspections can transform your business.

Upgrading to drone inspection systems empowers you to work safer, faster, and more efficiently. By embracing this technology, you reduce risks, cut costs, and gain access to high-quality data that can transform your operations. As you consider making the switch, take time to research the best solutions for your needs and explore how drones can fit into your workflow. Ready to take the next step? Reach out to our team or browse our resources to learn more about integrating drone inspections into your business.